Jan 11, 2025

Your freeze dryer just buzzed.

Your hash looks dry.

But is it really?

Here's the actual method for using ultimate vacuum to know when your hash is finished:

Ultimate vac 101

Please take this with a grain of salt — every batch is going to be slightly different.

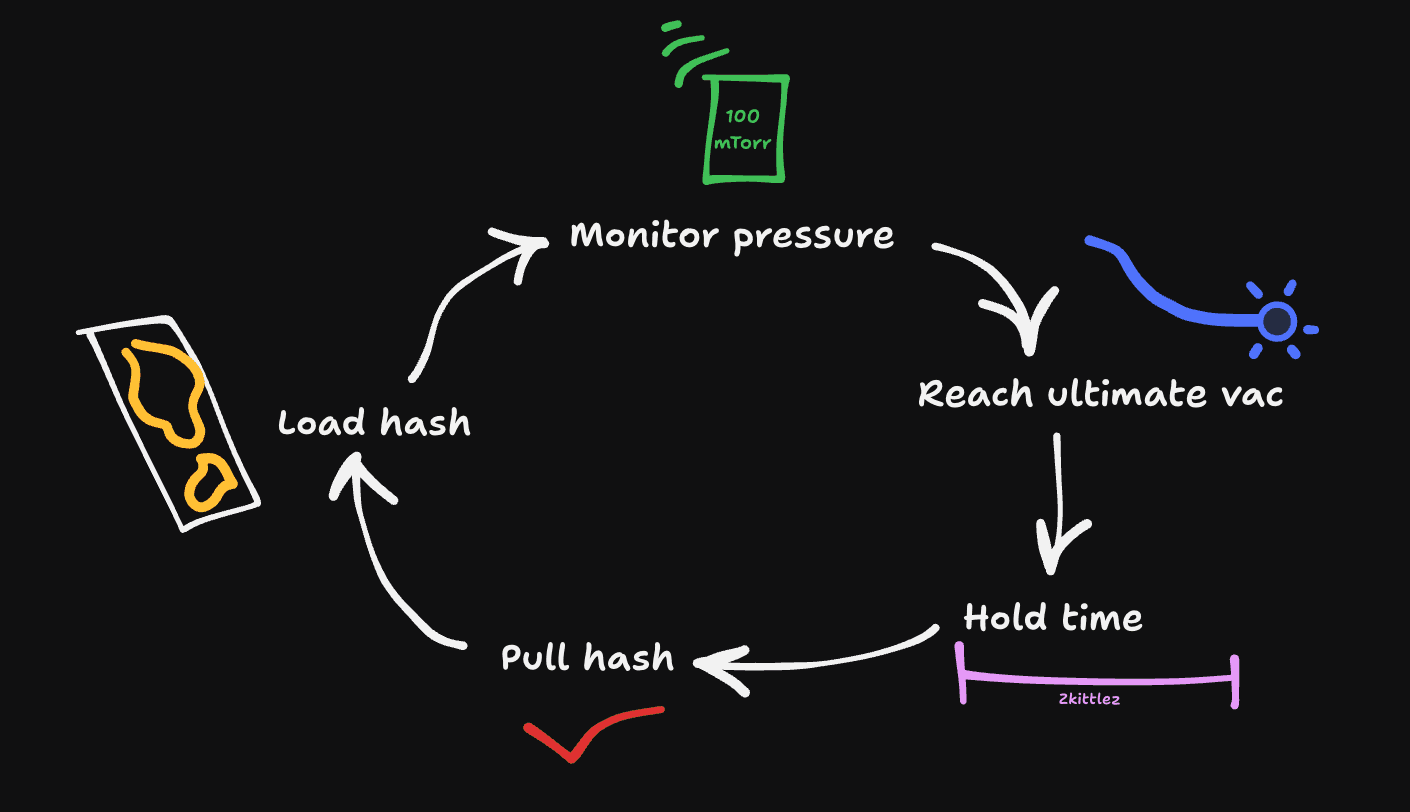

Load your hash and start your cycle

Monitor pressure until it reaches ultimate vacuum (typically 50-500 mTorr for Harvest Rights)

Time how long it holds at ultimate vacuum

Pull your hash based on your target hold time (this varies based on factors we'll cover below)

That's the core process. But like everything in hash making, there are a million other variables:

Finding your hold time

How long you need to hold your hash at ultimate vacuum will depend on:

Starting material moisture content

Batch size

Strain characteristics

Quality targets

Environmental conditions

^ These are all things that you should be recording to get dialed in anyways.

Start with 1-3 hours at ultimate vacuum and adjust based on your results. Some strains might need more time, others less. Document what works.

Now, let's go deeper

Ultimate vacuum is your freeze dryer's maximum capability - the lowest pressure it can achieve under ideal conditions. Think of it as your system's maximum vacuum potential. That's influenced by a bunch of different things:

Vacuum pump condition

Oil quality

Seal integrity

Overall system health

It sounds boring, but it can help you shave unnecessary time off of drying and tell you whether or not your freeze dryer is operating as expected.

Boring science context

During a proper freeze-drying run, your hash goes through two distinct phases:

Primary Drying (Sublimation)

This is where the magic happens. Free moisture turns directly from ice to vapor. Your vacuum readings will show dramatic changes as your system works to pull out all that vapor.

Secondary Drying (Desorption)

Now you're dealing with bound moisture - the stubborn stuff that takes much more work to remove. Your vacuum readings become more subtle, but just as important to watch.

Reading between the lines

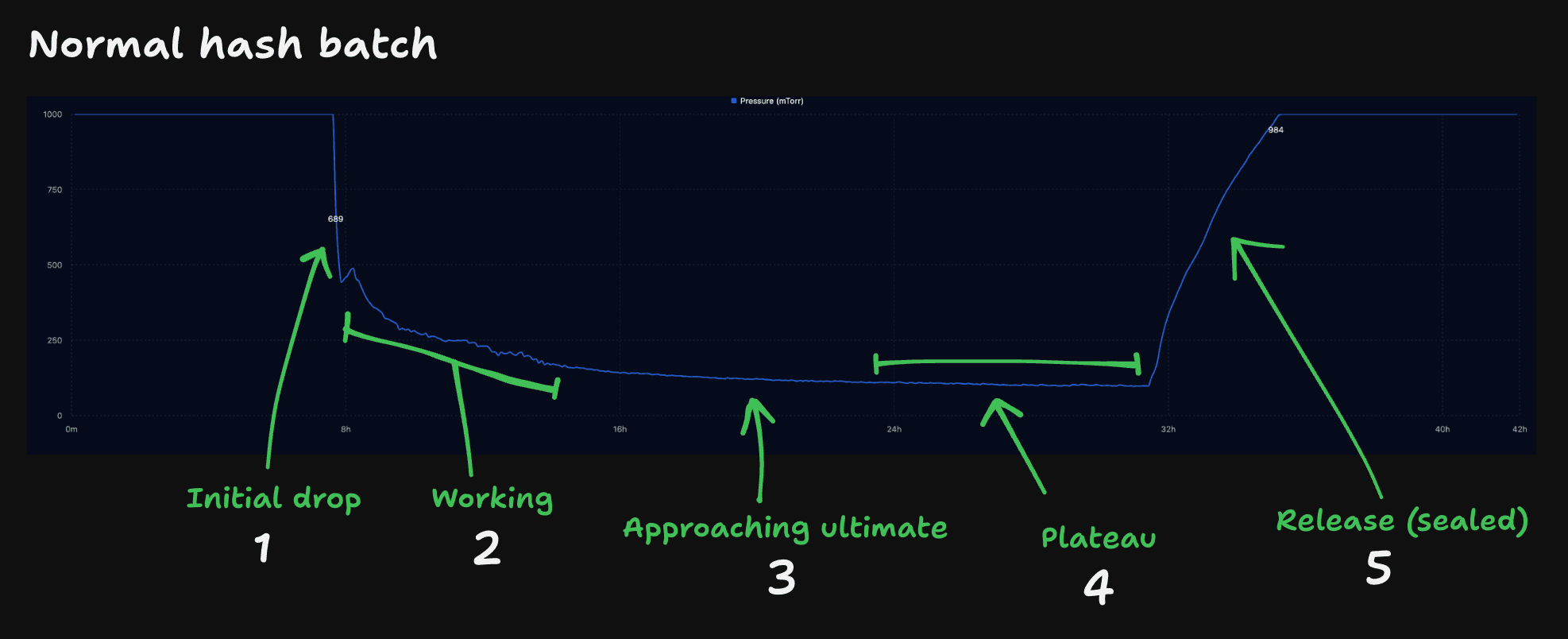

Your vacuum readings tell a story throughout the drying process:

Initial drop

Your system pulls down to operating pressure. This should happen quickly if everything's working right.

Working range

During primary drying, your pressure fluctuates as water vapor flows through the system. This is normal - you're actively pulling moisture.

Approaching ultimate

As less moisture is available for removal, your pressure starts trending toward your system's ultimate vacuum level.

Plateau

When your readings stabilize near your system's ultimate vacuum, you're in the final stages of drying.

Where stuff goes wrong

Poor vacuum performance isn't just an annoyance - it's costing you money. Here's what those readings might be telling you:

Can't Hit Ultimate Vacuum?

Oil needs changing

Door seal issues

Vacuum pump problems

Condenser temperature issues

Unstable readings…

Your freeze dryer is trying to tell you something. Maybe your condenser can't keep up. Maybe your pump is struggling. Either way, waiting until something breaks isn't an option.

Make your data work for you

Start building your vacuum profile library:

Track different strains/types of resin

Some types of resin need longer in secondary drying. Others dry quick, clean, and if you go too long, may start greasing on the tray. Understanding these patterns means less guessing.

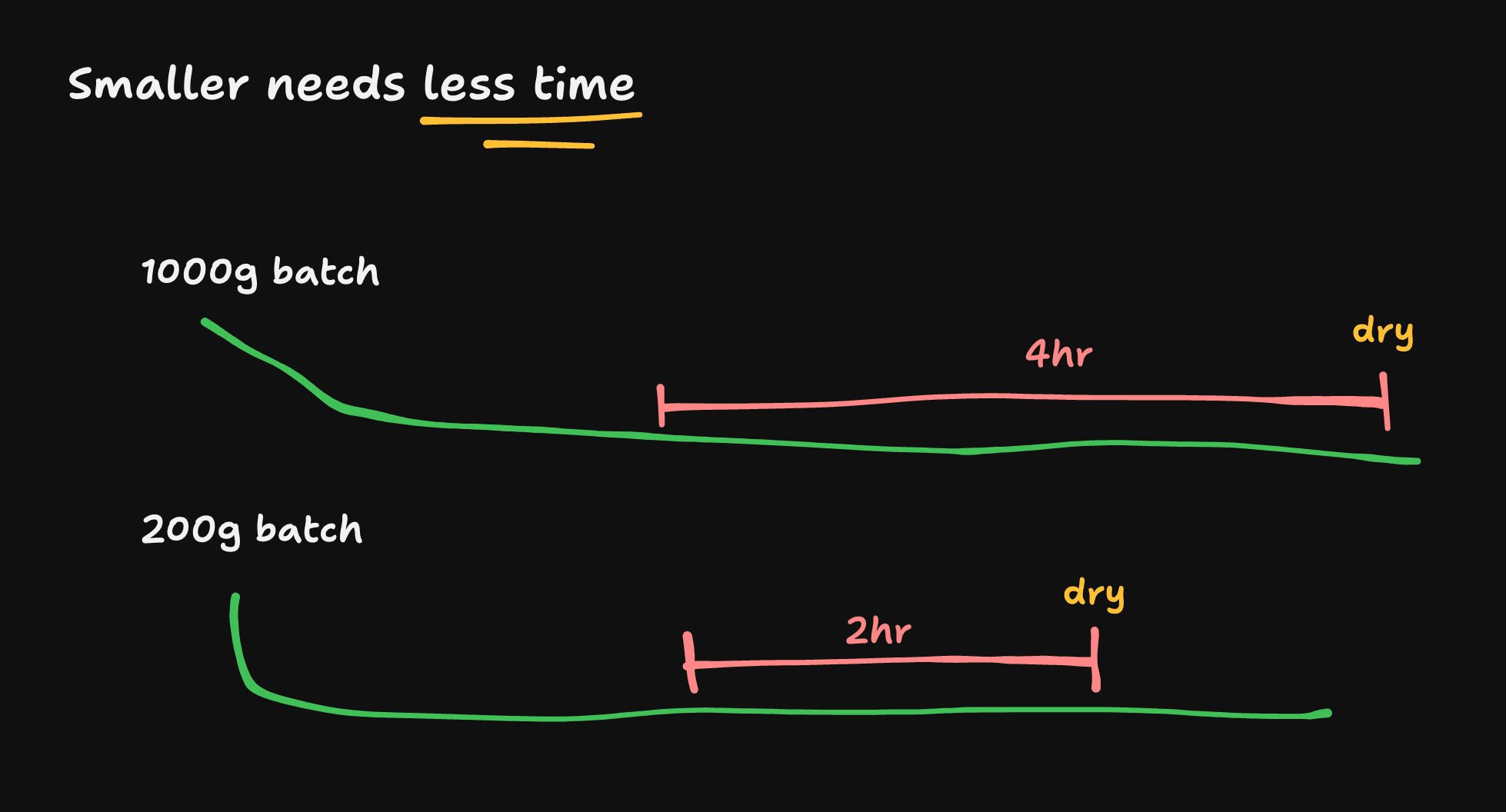

Monitor batch size

Bigger loads impact drying time and how much water vapor can be pulled out of the material at once. Different batch sizes will vary in how long they need at ultimate vacuum. Generally, smaller need less time and larger batches need more time.

We recommend keeping track of your wet weights and dry weights to properly determine how much water you're getting out of your hash every time, but we understand that that's a lot of work when you've got 10 million other things going on in the cold room.

So at the very minimum, keep track of your dry weights per freeze dryer.

This will help you develop a loose correlation between overall batch size and how much time it needs under ultimate vacuum.

We're adding weight inputs to the HashyLink app soon, so you'll be able to keep track of all that in one place.

Freeze dryer health

Regular vacuum monitoring catches issues before they become problems. It's cheaper to change oil than replace a pump. You can also spot issues like drain hoses causing slow vac leaks. Drastic changes in your ultimate vacuum level may indicate that it's time to change one of these things (usually oil change).

The "bottom line"

Ultimate vac isn't just about watching your mTorr bottom out. It helps you:

Make more money

Turn over batches faster

Less equipment failures

More consistent quality

Easy to repeat SOPs

Save time

Know when batches are actually dry

Stop babysitting your freeze dryer

Catch problems early

Run more efficiently

Build strain-specific recipes

Optimize batch sizes

Maintain equipment proactively

Here's how you can get started

Whether you're running a single home Harvest Right or a room full of pharmas, here's how you can get started monitoring your vacuum levels/ultimate vac.

Manual

Get a notebook or use your phone and start logging your readings every 15 minutes. It's better than nothing, and you'll miss subtle changes that ultimately matter, but this starts to give you a picture of how long your batches will need there.

There are a few hash makers doing this manually already or with cameras.

If you do it, you'll be drastically ahead of the curve.

Camera

You can use a camera aimed at your screen to partially automate the manual recording of vac readings, but you'll still have to note them down. At least you don't have to be in front of your freeze dryer.

Just get some security camera, aim it at your screen, and repeat the manual process. Check it every 15 minutes and note the vac level down to start developing a timeline for your batches.

Don't forget to record weights ;)

We've thought about making a way to import data from these camera feeds into our app, and we've heard of people trying to do this, but it's hard to do well and it's cumbersome.

If you want this functionality, let us know.

Autopilot

Let some machine do all this boring monitoring stuff so you can focus on the hash. Modern systems like HashyLink can alert you when you hit key vacuum levels or if something's off.

We're currently working with hash makers to further develop our live vacuum monitoring features specifically for dialing in drying for hash. We started with graphing, but we're working on a timer that will learn from your batches as you enter different weights and identify your ideal dryness.

The future is… less spreadsheets and paper notes

Hash makers aren't just artists — they're scientists. And accountants. And operations specialists. And sales leaders.

You don't also need to be doing a bunch of pointless manual data entry on top of all that.

Let us take ONE thing off your back.

Throw a HashyLink in your freeze dryers and let us do the monthly reports for you. We'll work with you to find the perfect window for each of your freeze dryers and different batches.

You can keep running on timers and hunches. Or you can let the data guide you to better hash.

The choice is yours.

Data is still pretty unpopular at the time of initial writing, so if you do this, you'll be ahead of a lot of the market.

---

Want to dive deeper into vacuum monitoring? Hit us up with questions!